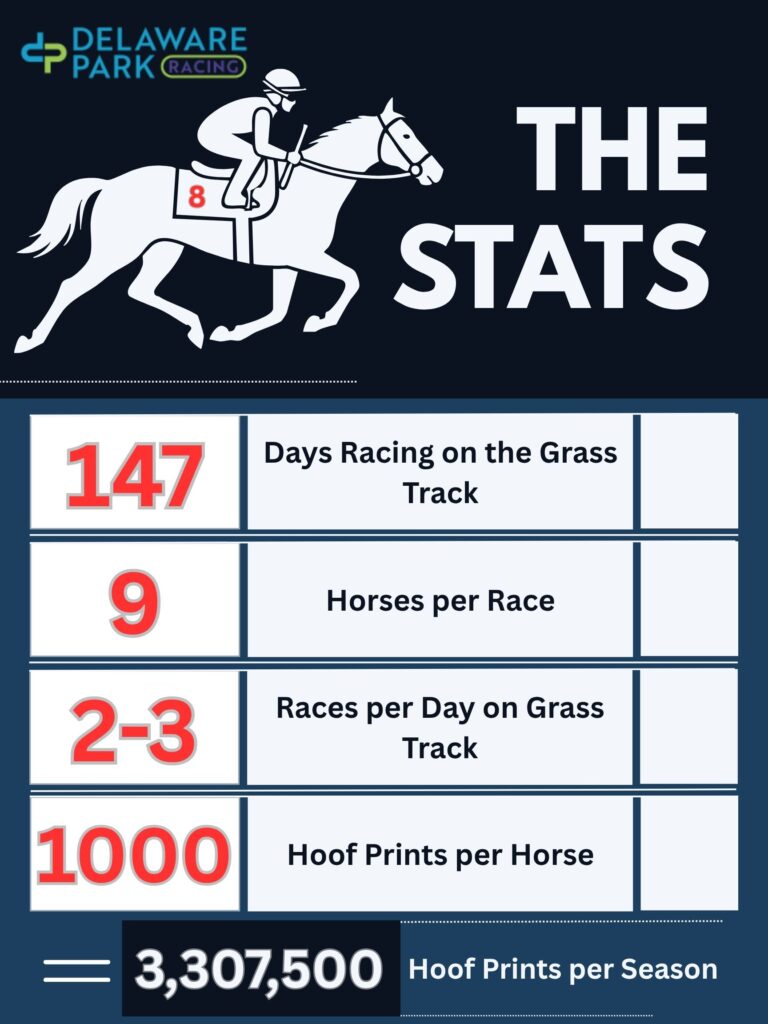

3,307,500 Hoof Prints Per Year:

How Delaware Park Keeps Its Turf Track in Winning Condition

We talk a lot about soil compaction and the force that is applied to turf by human athletes on athletic fields or pedestrian foot traffic applied to lawns of public parks, but none of this comes close to the damage a horse can do galloping at 40 miles an hour.

Imagine for a moment what happens to the turf of a grass racetrack when a field of 1000 lb. horses gallop circuits an average of 150 times per season.

Recently, Jerome (Jed) Doro, Director of Racing at Delaware Park Casino and Racetrack, was kind enough to give us a tour of his track, sharing his turf care program. Not surprisingly, topdressing with LVS TurfSoil is a key part of his program, managing extreme divots and compaction. He provided the following mind-blowing perspective of the wear and tear the turf course endured throughout the 2025 racing season.

In 2025, Delaware Park was scheduled to race thoroughbreds every day, from May 14 to October 18, on their grass track. The rainy spring delayed the start of the season until Memorial Day weekend, which then provided 21 weeks of racing.

So let’s do some fun math:

The Strategy

Delaware Park is blessed with a large turf track. It is so wide that they can employ an adjustable inside rail that can be moved in and out between racing days, spreading out traffic, thus minimizing concentrated wear areas.

Additionally, after the racing season concludes in the Fall, Jed’s grounds team aerates the soil and overseeds with fescue. Then they topdress with LVS TurfSoil. Topdressing in the Fall is particularly important, as cooler weather conditions are ideal for the cool-season turf, giving the seed time to germinate and develop a good root system before going dormant over the winter.

In 2025, opening day was delayed by two weeks because of rainy weather. Jed feels that this extra time created the strongest root system he has seen, as evidenced by the quality of the track conditions throughout the racing season.

He wasn’t the only one who noticed. Horse trainers, spectators, and coworkers also commented on how well the course held up over the season.

Jed commented, “The course looked like it was raced on but not devastated like in previous years.”

Ricky Hendricks, a top local trainer, said that the turf is so good here, he considers it the safest course around for his horses.

Consistency is Key

Jed also feels that the cumulative effect of using LVS TurfSoil has improved their turf.

Before they discovered Laurel Valley Soils, they were using a variety of different and inconsistent topdressings, and as a result, had inconsistent and unreliable results. The track quickly improved once they began exclusively using TurfSoil. They also always keep a supply on hand at their maintenance shop so they can fill in the worst divots after each day’s racing.

When asked what he feels are the key elements for maintaining his highly rated turf track, which is the only one in Delaware, he said:

- Use quality topdressing material. LVS TurfSoil is a game changer, as it performs double duty. The compost component helps lighten up the root zone, and the soil helps level out the surface.

- Be more diligent with maintenance: move the turf rail, fix divots daily, overseed, and commit to a spring and fall maintenance plan.

Our STA Certified TurfSoil is most successful at combating soil compaction and maintaining a robust, healthy turf. Blended with our TurfDress Compost, the organic matter provides excellent soil aggregation and pore space, resulting in good infiltration during rain events as well as good moisture-holding capacity in dry times.

Want to know more about LVS TurfSoil and our topdressing solutions?

Contact us at 610-268-5555 to discuss how we can help you create healthier, championship-grade turf.